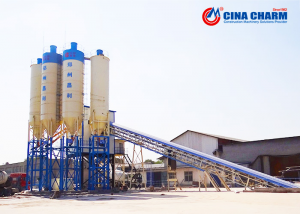

HZS90 concrete batching plant

Production Description

HZS90 concrete batching plant is mainly composed of 5 major systems including mixing host, material weighing system, material conveying system, material storage system and control system and other auxiliary facilities. The concrete mixing station is mainly divided into four parts: sand and gravel feeding, powder feeding, water and admixture feeding, transmission and mixing and storage. The material weighing system is vertical feeding and measurement, which saves measurement time and greatly improves Productivity.

Feature:

1. Concrete batching machine is used for the aggregates batching for concrete mixing station. The aggregates can be 2-4 types, such as coarse stone, fine stone, sand and others. The proportion of each aggregate is weighed automatically controlled by microcomputer.

2. The mixer is equipped with multiple shaft end sealing protection devices and wind pressure sealing protection devices, which can effectively prevent the occurrence of slurry phenomenon, heavy design, and stable operation.And have high single-time mixing capacity.

Fully automatic control system, easy to operate, can effectively save manpower and material resources, fast and efficient.

Technical parameters

|

Model |

HZS90 |

|

Capacity(m3/h) |

90 |

|

Mixer |

JS1500 |

|

Discharging height (M) |

4.1 |

|

Aggregate Batching machine |

PL3200 |

|

Hoisting mode |

Belt conveyor |

|

Screw conveyor |

LSY273 |

|

Cement silos |

100 ton/200 ton |

|

Aggregate metering accuracy |

±2 % |

|

Cement metering accuracy |

±1 % |

|

Fly ash metering accuracy |

±1 % |

|

Water metering accuracy |

±1 % |

|

Additive metering accuracy |

±1 % |

Product Show

Details show

Installation details

Sale service

Modular design for convenient and fast installation, maintenance, relocation and tranportation.